Creating a print-ready file for vehicle wraps is essential for ensuring that your design appears perfectly on the vehicle. First, start with an accurate template to match the vehicle’s precise dimensions. Next, pay attention to the specifications of the vehicle, especially if it has unique shapes or moving parts. Using vector graphics is crucial because they maintain quality when scaled; raster images should be high resolution. Remember to set your file in CMYK color mode for printing and include adequate bleed margins—at least 2-4 inches is often best in this case. Finally, check everything with your printer before submitting files!

1. Start with the Right Template

Starting with the right template is crucial for a successful vehicle wrap design. An accurate template reflects the exact dimensions and contours of the vehicle. This ensures that the design fits well and aligns with the vehicle’s features, such as curves and edges. If the client cannot provide a template, you can often obtain one from the printing service you plan to use. Be cautious with templates found online; they may not capture all the vehicle’s nuances. For instance, a template for a delivery van should indicate not only the flat surfaces but also the areas around handles and windows, which can affect how the wrap looks once applied. Using a precise template saves time and prevents costly mistakes during the printing and installation processes.

2. Understand the Vehicle’s Specifications

When creating a vehicle wrap, it’s crucial to understand the specific dimensions and contours of the vehicle being wrapped. Each vehicle type has its own unique characteristics that can affect the design. For instance, a large delivery van will require a design that utilizes its expansive surface area effectively, ensuring it looks balanced without being cluttered. On the other hand, a compact car may need a more streamlined design to avoid overwhelming its smaller surface. Additionally, consider the vehicle’s purpose. A food truck, for example, must have prominent branding and menus that remain visible even when doors are open. Being mindful of features like windows, handles, and curves is essential as these can impact where you place critical elements like logos or messages. For the best results, gather accurate measurements and even photographs of the vehicle to guide your design process.

- Measure the specific dimensions of the vehicle’s surfaces for coverage.

- Identify the different panels and areas that will be wrapped.

- Consider the curvature and contour of the vehicle when designing.

- Research the manufacturer’s specifications for materials and finishes.

- Understand how the vehicle’s year, make, and model affect the design process.

- Check for any environmental regulations affecting wrap materials.

3. Use Vector Graphics

Credits: graphicmama.com

Credits: graphicmama.com

When designing your vehicle wrap, it’s crucial to use vector graphics as much as possible. Vector files, like those saved in AI, EPS, or PDF formats, are made up of paths defined by mathematical equations, allowing them to scale without losing quality. This means that whether your design is printed at the original size or significantly enlarged, it will remain sharp and clear. On the other hand, raster images (like JPEG or PNG) can become pixelated when scaled up, which can detract from the overall appearance of the wrap. If you have to use raster images, make sure they are high-resolution—at least 300 DPI at full scale—to maintain clarity. Additionally, if you’re working with programs like Photoshop, keep your files layered to preserve vector qualities where applicable. This practice will ensure that your wrap looks professional and vibrant when printed.

4. Set the Correct Resolution and Color Mode

To achieve the best print quality for your vehicle wrap, it is essential to set the correct resolution and color mode. Start by using CMYK color mode, which is tailored for printing. This contrasts with RGB, which is used for digital displays and may not translate well in print. When designing at full scale, aim for a resolution of at least 150 DPI. However, if you’re working at a smaller scale, let’s say 1:10, adjust your output resolution accordingly to maintain image clarity. For example, if your design is at 1:10 scale, you should set your resolution to 1500 DPI to ensure every detail appears crisp and vibrant once printed. This attention to detail in resolution and color settings can significantly impact the final appearance of the wrap, ensuring it stands out effectively on the road.

| Tip | Details |

|---|---|

| Use Vector Graphics | Aim to use vector graphics such as AI, EPS, or PDF formats to maintain quality during scaling. Raster images should be at least 300 DPI at 100% scale. |

| Set the Correct Resolution and Color Mode | Use CMYK color mode for print files and aim for at least 150 DPI. Adjust the resolution if working at a reduced scale. |

| Add Bleed Margins | Include a bleed of 2-4 inches for vehicle wraps to avoid white spaces after trimming. |

| Keep Important Elements Away from Edges | Position text and logos at least 2 inches away from the edges to prevent cutting off during installation. |

| Communicate with Your Printer | Confirm file requirements with your printer to avoid delays and additional costs. |

5. Add Bleed Margins

When creating your vehicle wrap design, it’s essential to include bleed margins to ensure a clean and professional finish. Bleed is the area that extends beyond the actual dimensions of your design. A minimum bleed of 0.125 inches is standard, but for vehicle wraps, it’s advisable to increase this to between 2 to 4 inches. This extra space allows for any slight misalignments during installation and helps prevent any unwanted white edges from appearing along the wrap. For example, if your design is meant to cover the full side of a van, adding bleed will ensure that the wrap covers the entire surface, even if the material shifts slightly during application.

6. Keep Important Elements Away from Edges

Credits: blog.teelaunch.com

Credits: blog.teelaunch.com

When designing a vehicle wrap, it’s crucial to keep important elements like text and logos away from the edges. This helps to ensure that they are not accidentally cut off during the printing and installation process. A good rule of thumb is to keep these elements at least 2 inches from the edges. For instance, if you’re placing a logo, position it well inside the borders of the design. This not only protects the integrity of your design but also ensures that key information remains visible and legible, even if the wrap shifts slightly during application.

7. Consider the Installation Process

When designing a vehicle wrap, it’s crucial to think about how it will be installed on the vehicle. Different vehicles come with their own unique shapes, curves, and features, which can affect the installation process. For instance, avoid intricate patterns that may be difficult to align. Instead, opt for simpler designs that can easily wrap around the vehicle’s contours. If your design involves multiple panels, ensure they fit together smoothly to minimize visible seams. This not only enhances the overall appearance but also simplifies the installation for the professionals applying the wrap. Additionally, consider any obstacles on the vehicle, such as door handles, mirrors, or windows, and design accordingly to ensure that critical elements are not obstructed during the application.

8. Use High-Quality Images

Using high-quality images in your vehicle wrap design is essential for achieving a professional look. When selecting images, choose those that are at least 300 DPI at the size they will be printed. This ensures that the image remains sharp and clear, even from a distance. For example, if you’re including a photo of a product on the wrap, opt for a high-resolution image that showcases the product’s details. Additionally, consider the source of your images; using stock images from reputable providers can help you avoid issues with quality and copyright. Remember, a stunning design can be undermined by pixelated or blurry images, so always prioritize quality.

9. Communicate with Your Printer

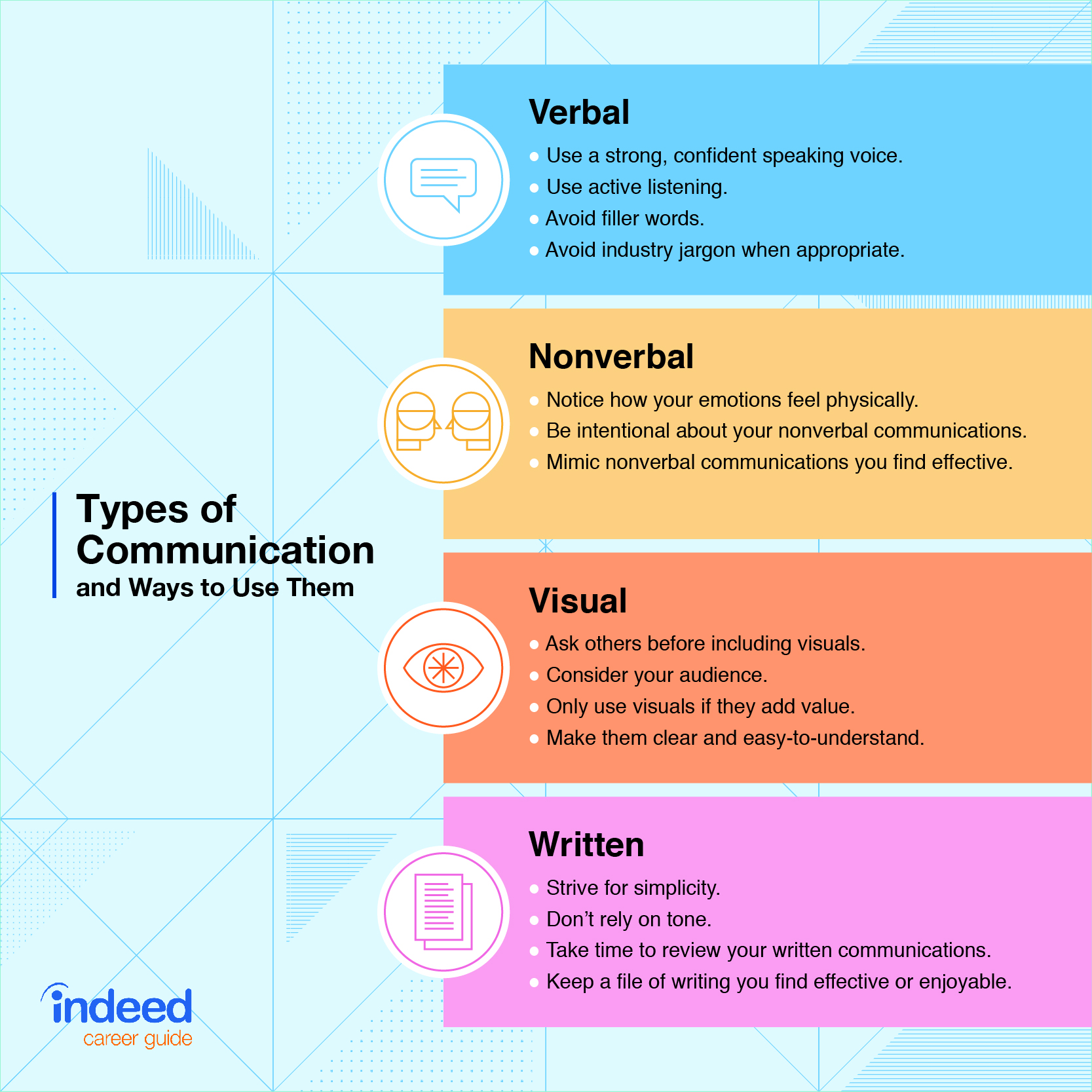

Credits: indeed.com

Credits: indeed.com

Before you finalize your design, it’s crucial to have a conversation with your printer. Different printing companies might have unique specifications regarding file formats, size, and color profiles. For instance, some printers may prefer files in PDF format while others might ask for AI or EPS files. Additionally, discussing color profiles is vital; ensure that your printer accepts CMYK since this is standard for print production. Not only does this help in meeting their requirements, but it can also prevent delays in the printing process. If you’re unsure about any specific requirement, don’t hesitate to ask. Clear communication helps ensure that your design will be printed exactly as you envision it.

10. Review and Proof Your Design

Before you submit your files for printing, it’s crucial to carefully review your design for any errors or issues. Check the layout to ensure everything is aligned correctly and that text is legible. Pay close attention to colors; sometimes, what looks good on your screen may not translate the same way in print. One effective method is to create a printed proof of your design. This allows you to see how the colors and elements appear on paper, giving you a better sense of what the final product will look like. For instance, if your design includes a vibrant red, confirm that it prints as expected instead of appearing darker or duller. Additionally, look for any typos or mistakes in your text. Even a small error can become glaring when seen on a large vehicle. A fresh pair of eyes can also help, so consider asking a colleague to review your design as well. This step is essential to ensure that the final product meets your expectations and avoids costly reprints.

Frequently Asked Questions

1. What file type should I use for a vehicle wrap design?

For vehicle wraps, it’s best to use file types like PDF, AI, or EPS because they maintain high quality for printing.

2. How do I know the right size for my vehicle wrap file?

You need to measure the areas of the vehicle you want to wrap, then create your design based on those measurements.

3. Why is it important to use high-resolution images in my design?

High-resolution images ensure that your design looks sharp and clear when printed, preventing any pixelation.

4. What color mode should I use for my vehicle wrap file?

You should use CMYK color mode, as it’s the standard for print production, ensuring your colors come out accurately.

5. How can I ensure my design lines up correctly on the vehicle?

You can create a template of the vehicle shape and outlines, using that as a guide for your design to ensure perfect alignment.

TL;DR To create a print-ready file for vehicle wraps, start with an accurate template of the vehicle and understand its specifications. Use vector graphics for scalability and set your color mode to CMYK with a resolution of at least 150 DPI. Include sufficient bleed margins, keep important design elements away from edges, and consider the installation process. Use high-quality images and communicate with your printer about their specific file requirements. Finally, review and proof your design to ensure quality before printing.