Creating your own sunglasses or glasses frames is not only a fun project but also allows you to showcase your creativity. To start, gather essential materials like acetate sheets for shaping frames, wood blocks for wooden styles, or metal sheets if you’re aiming for a sleek look. Once you’ve collected the necessary tools and lenses, sketch out your unique design. This involves cutting and assembling the chosen materials carefully—gluing wooden pieces together or heating acetate to achieve the desired shape. After fitting in the lenses and securely attaching hinges, don’t forget to sand down any rough edges. Finally, wear your custom creation with pride!

1. Overview of Crafting Your Own Sunglasses

Crafting your own sunglasses is an exciting blend of creativity and functionality. It allows you to express your personal style while ensuring a perfect fit for your face. The process involves designing the frames, selecting materials, and assembling the pieces with precision. Whether you choose to work with wood, acetate, or metal, each material brings its own unique qualities to the finished product. For instance, wooden frames offer a natural aesthetic and can be surprisingly lightweight, while acetate allows for vibrant colors and intricate designs. As you embark on this project, consider the intended use of your sunglasses—whether for fashion, sports, or everyday wear—as this will influence your design choices. Engaging in this hands-on project not only results in a custom pair of sunglasses but also enhances your skills in craftsmanship and design.

2. Materials Needed for Custom Eyewear

To create your custom eyewear, you’ll need a variety of materials tailored to the type of frames you wish to make. First, consider the frame materials. Acetate is a popular choice due to its lightweight nature and the ability to mold it into various shapes and colors; you can find acetate sheets in craft stores. If you prefer something more natural, hardwoods like walnut or oak are excellent for wooden frames. You’ll need wooden blocks cut to the desired dimensions, and a saw to shape them. For metal frames, materials like stainless steel, aluminum, or titanium are recommended, and you’ll need metal sheets along with welding tools if you’re crafting a more complex design. Alternatively, TR90 is a thermoplastic that offers flexibility and impact resistance, ideal for sporty sunglasses.

Next, focus on the lens materials. High-quality polarized lenses are essential for protecting your eyes from harmful UV rays. You can repurpose lenses from old sunglasses or purchase new ones online. It’s also vital to have hinges and fasteners, which are necessary for attaching the arms to the frames. These can be salvaged from old pairs or bought from eyewear suppliers.

Adhesives play a crucial role in holding your frames together. Wood glue is suitable for wooden frames, while epoxy works best for acetate and metal, as it forms a strong bond. Tools are also necessary for the crafting process. Cutting tools like a CNC machine, laser cutter, or even a scroll saw will help you shape your materials. A drill or drill press is needed for making holes for the hinges, and sandpaper will be essential for smoothing edges and surfaces. Lastly, consider using CAD software to design your frame templates, ensuring precision in your measurements.

| Material Type | Description | Usage |

|---|---|---|

| Frame Materials | Acetate: A lightweight and durable plastic that can be molded into various shapes and colors. | For crafting frames. |

| Wood: Hardwood options like walnut or oak recommended. | For wooden sunglasses. | |

| Metal: Stainless steel, aluminum, or titanium. | For metal frames. | |

| TR90: A thermoplastic known for flexibility and impact resistance. | For sports sunglasses. | |

| Lens Materials | High-quality polarized lenses are recommended. | Used for clear vision. |

| Hinges and Fasteners | Hinges are required to attach arms to frames. | For ease of use. |

| Adhesives | Wood Glue: For wooden frames. | To bond wooden pieces. |

| Epoxy: For metal and acetate frames. | To ensure a strong bond. | |

| Tools Required | Cutting Tools: CNC machine, laser cutter, scroll saw. | For cutting materials. |

| Drill/Drill Press: For making hinge holes. | For functionality. | |

| Sandpaper/Sanders: For smoothing edges. | To enhance appearance. | |

| CAD Software: For designing templates. | For accuracy. |

3. Step 1: Designing Your Frames

Credits: coastalkelder.com

Credits: coastalkelder.com

Begin your journey by sketching out the design of your sunglasses or glasses frames. Consider the overall shape and size, keeping in mind your personal style and comfort. If you prefer precision, use CAD software to create detailed designs that can be easily adjusted.

Once you have your design, create a template from your sketches. For wooden frames, you can trace the shape of an existing pair of sunglasses to ensure a good fit. If you’re working with acetate or metal, mark out your dimensions on the material according to your template. This is an important step as it sets the foundation for your entire project.

Don’t forget to think about the details, such as the width of the frames, the height of the lenses, and the curvature for comfort. Each of these factors will influence the final product, so take your time to get them right.

4. Step 2: Preparing Your Materials

To prepare your materials for crafting sunglasses or glasses frames, start by gathering everything you need based on your chosen frame material. For wooden frames, cut the wood into smaller pieces according to your design dimensions. If you need a specific thickness, resaw the wood accordingly. For acetate or metal frames, use your templates to cut the sheets into the required shapes. Make sure to use appropriate cutting tools, like a CNC machine or laser cutter, for clean edges. Additionally, ensure all materials are smooth and free from splinters or rough patches, as this will impact both the aesthetics and comfort of your finished sunglasses. Keep all your tools organized and within reach to streamline the production process.

5. Step 3: Cutting and Assembling Frames

Start by cutting your frame pieces according to the design you created. For wooden frames, use a scroll saw or coping saw for accurate cuts. Ensure each piece matches your template closely. If you are working with acetate, a laser cutter or CNC machine will give you precise shapes. For metal frames, carefully measure and cut using a metal saw. Once all pieces are cut, it’s time to assemble.

For wooden frames, apply wood glue to the edges where the pieces will join. Use clamps to hold them tightly together until the glue dries completely. This ensures a strong bond. If you are crafting acetate frames, heat the acetate to make it pliable, then mold it around your template. Once cooled, polish the frames to remove any rough edges.

For metal frames, after cutting, you will need to weld or use screws to join the pieces. Make sure the joints are secure and check for any sharp edges that could cause discomfort. Take your time during this step to ensure everything fits together well, as this will affect both the aesthetics and comfort of your finished sunglasses.

- Use a precision cutting tool to ensure clean edges

- Measure the frame dimensions accurately

- Cut the frame pieces according to the design plan

- Smooth out any rough edges with sandpaper

- Align the frame pieces carefully before assembly

- Use strong adhesive or a soldering method to assemble the frames

- Allow the adhesive to cure fully before proceeding to the next steps

6. Step 4: Adding Lenses to Your Frames

Credits: sunglassville.com

Credits: sunglassville.com

To add lenses to your custom frames, start by ensuring that your lenses match the shape and size of your frame. If you’re using pre-cut lenses, this step will be straightforward. However, if you need to cut lenses, carefully measure the lens openings in your frames and cut the lenses accordingly, using a glass cutter or specialized lens-cutting tool for precision.

For wooden frames, create a countersink in the frame where the lenses will sit. This ensures that the lenses fit snugly and securely. If you’re working with acetate or metal frames, ensure the openings are smooth to prevent any scratching or damage to the lenses.

Once the lenses are ready, gently fit them into the frames. For added security, you may choose to apply a small amount of adhesive around the edges of the lenses. Be cautious not to use too much glue, as it could seep into the lens area and impair visibility.

After fitting the lenses, take a moment to check for any gaps or misalignments. Adjust as necessary to ensure a perfect fit. Remember, a snug fit will not only enhance the aesthetics of your eyewear but also ensure durability and comfort during wear.

7. Step 5: Attaching Hinges and Fasteners

Attaching hinges is a crucial step in ensuring your sunglasses or glasses frames function properly. Start by marking the spots on the frame where the hinges will be placed. Typically, these are located at the junction where the arms meet the front of the frame. Once marked, use a drill or drill press to create precise holes for the hinges. Be careful to choose a drill bit that matches the size of the screws you will be using.

Next, take your hinges—these can be either salvaged from old frames or purchased from an eyewear components supplier. Align the hinges with the pre-drilled holes and secure them in place using screws. Make sure they are tightened adequately to avoid any wobbling but be cautious not to overtighten, as this may strip the screws or damage the frame.

For frames made from materials like acetate or wood, you can also use epoxy as an alternative to screws for a more seamless look. Apply the epoxy to the hinge before placing it in position and hold it until it sets. This method can provide a clean finish and is particularly useful if you prefer not to see visible screws on your frames.

After attaching the hinges, test the movement of the arms. They should open and close smoothly without excessive resistance. If they feel stiff, check the alignment and ensure that there are no obstructions. Properly attached hinges will enhance the durability and usability of your custom eyewear.

8. Step 6: Finishing Touches for a Polished Look

To give your sunglasses or glasses frames a professional finish, start by sanding the surfaces to eliminate any rough edges. Use coarse sandpaper first to remove larger imperfections, progressing to finer grades for a smooth touch. Pay special attention to any corners or curves, ensuring they feel comfortable against your skin. Once you achieve the desired smoothness, consider applying a protective finish. For wooden frames, natural oils like olive oil or a wax finish such as beeswax can enhance the wood’s color and grain while providing protection against moisture. For acetate or metal frames, a suitable polish can add shine and help resist scratches. Be sure to let any finishes dry completely before wearing your new creations. Finally, check the frames for any last-minute adjustments or imperfections. This attention to detail will ensure your eyewear not only looks great but also feels comfortable and durable.

9. Step 7: Testing and Adjusting Fit

Credits: revantoptics.com

Credits: revantoptics.com

After assembling your sunglasses, it’s crucial to test the fit. Put on the frames and check for comfort. Ensure the arms sit snugly against your head without pinching. If they feel too tight, you can gently bend the arms outward. On the other hand, if they are loose, consider adjusting the hinges or adding padding. For wooden frames, sanding down any rough edges can enhance comfort. Remember, the goal is to have a secure yet comfortable fit that allows you to wear them for extended periods without discomfort. If you notice any pressure points, make adjustments accordingly, as a good fit is essential for both function and style.

10. Step 8: Enjoying Your Custom Sunglasses

Finally, it’s time to enjoy your custom sunglasses! Put them on and admire your handiwork. You’ve taken a vision and turned it into a tangible accessory that reflects your personal style. Whether you made them for a specific occasion or just for fun, wearing something you’ve crafted adds a unique touch to your outfit.

Take some time to show off your creation to friends and family. Share the story of how you made them, from the initial design to the final touches. Not only do you get to enjoy your custom eyewear, but you can also inspire others to try their hand at crafting their own sunglasses.

Consider using your sunglasses in different settings—whether at the beach, during outdoor activities, or simply for a casual day out. Each time you wear them, you’ll appreciate the effort and creativity that went into making them. Plus, if you’ve chosen materials that suit your lifestyle, like sports lenses for active days, you’ll find them both functional and stylish.

Frequently Asked Questions

1. How do I choose the right materials for making sunglasses or glasses frames?

Select materials that are durable and comfortable. Common choices include plastic, metal, and wood. Think about what feels good on your face and lasts long.

2. What tools do I need to create my own sunglasses or glasses frames?

You will need basic tools like scissors, a screwdriver, a saw for cutting materials, and a drill for making holes. Having a good workspace helps a lot, too.

3. Can I customize the shape of my sunglasses or glasses frames?

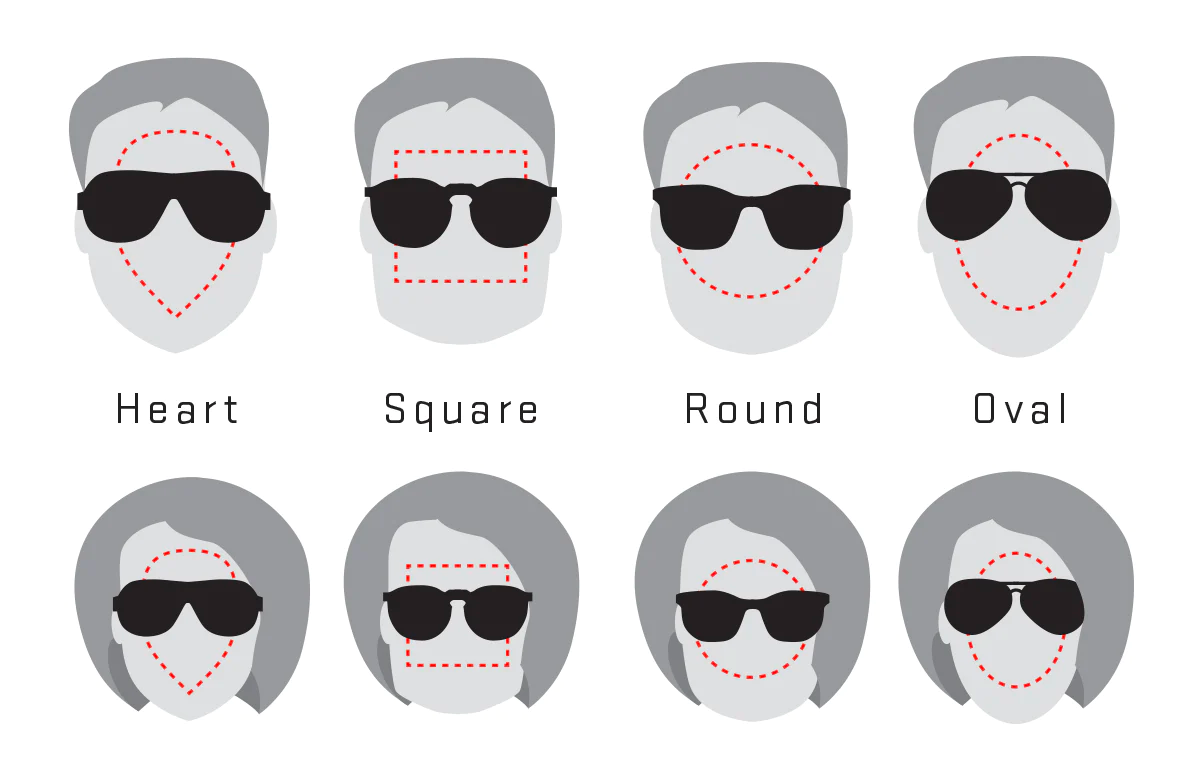

Yes, you can! Use templates or design your own shape. Just remember to measure carefully to ensure they fit well on your face.

4. What are some tips for fitting my glasses frames properly?

Make sure the frames sit comfortably on your nose and ears. They shouldn’t slide down or pinch. You can adjust the arms for a better fit too.

5. How can I make my sunglasses or glasses frames look unique?

You can add personal touches like colorful designs, patterns, or even engraving. Use paints or decals to express your style!

TL;DR This guide provides a comprehensive step-by-step process for crafting your own custom sunglasses or glasses frames, covering materials like acetate, wood, metal, and TR90, along with essential tools. Key steps include designing your frames, preparing materials, cutting and assembling, adding lenses, attaching hinges, and applying finishing touches. The project culminates in a personalized eyewear creation that reflects your style and craftsmanship.