Printed Circuit Boards (PCBs) are crucial in today’s electronics, connecting various components seamlessly. For beginners, designing a PCB can seem overwhelming; however, using a structured approach simplifies this task significantly. Start by clearly defining your circuit requirements and drafting a schematic to guide the design process. Next, choose user-friendly PCB design software like KiCad or EasyEDA that suits your needs. Once you’ve created the schematic, focus on defining the physical layout and routing traces efficiently to minimize interference. After verifying with essential checks and generating Gerber files for manufacturers, you’ll be ready to order your custom PCB—leading you into the world of electronics design!

1. Understand Your Circuit Requirements

Credits: protoexpress.com

Credits: protoexpress.com

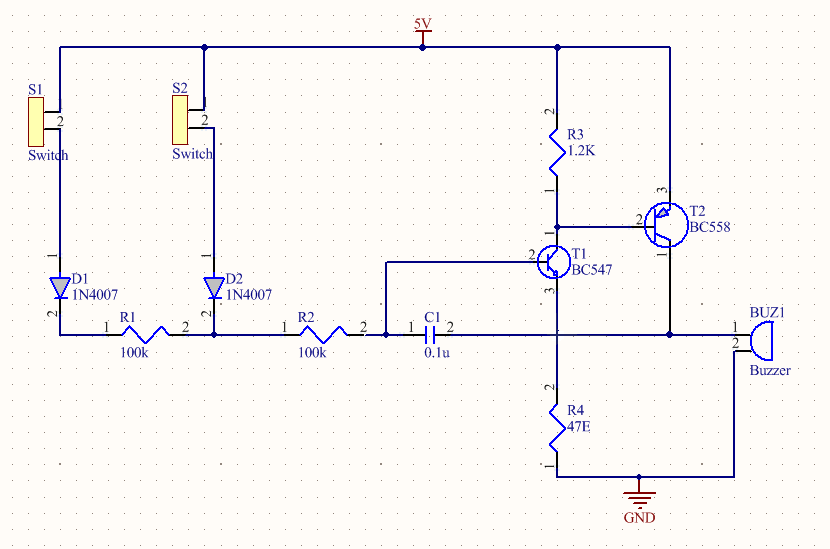

Before starting your PCB design, it’s crucial to understand exactly what your circuit needs to achieve. Begin by outlining the function of your circuit—what it will do and how it will operate. For instance, if you’re designing a simple LED circuit, consider how many LEDs you want to use, their voltage requirements, and how they’ll be powered.

Next, draft a schematic that includes all necessary components. This could be done on paper or through software tools. Make sure to include every element, such as resistors, capacitors, and microcontrollers, along with their connections. This schematic acts as a roadmap for your PCB, guiding you through the layout and ensuring that all components will work together as intended.

It’s also important to think about the electrical specifications—like voltage and current ratings—so that your components can handle the requirements without overheating or failing. If your circuit involves sensors or communication modules, note their specific needs as well. By clearly defining your circuit’s requirements and drafting a detailed schematic, you’ll set a strong foundation for the subsequent steps in your PCB design process.

2. Choose Your PCB Design Software

Selecting the right PCB design software is crucial for beginners. There are a variety of options available, each with its unique features and advantages.

KiCad is a popular choice among hobbyists and professionals alike. It is free and open-source, offering a comprehensive set of tools for both schematic capture and PCB layout. Its active community also provides support and resources, making it easier for newcomers to learn.

Eagle is another widely used software known for its user-friendly interface and powerful features. It offers a free version for small boards, which is perfect for beginners. Eagle’s integration with Autodesk tools makes it a strong choice for those already familiar with their software ecosystem.

For those who prefer working online, EasyEDA is an excellent option. It offers an extensive component library and collaborative features that allow you to share designs easily. Its intuitive interface is particularly appealing for beginners, as it simplifies the design process.

When choosing software, consider your specific needs, budget, and the learning curve associated with each tool. For most beginners, KiCad and EasyEDA provide a great balance of functionality and ease of use.

| Software | Description | Key Features |

|---|---|---|

| KiCad | A free and open-source option with a comprehensive set of tools. | User-friendly, extensive libraries, cross-platform compatibility |

| Eagle | Known for its user-friendly interface and powerful features. | Rich feature set, strong community support, flexible licensing |

| EasyEDA | An online tool with an extensive component library and easy sharing capabilities. | Cloud-based, easy collaboration, rich component library |

3. Create the Schematic

To create the schematic, start by placing all the components you identified in the previous steps onto your workspace in the design software. Make sure to include every component your circuit needs, such as resistors, capacitors, and ICs. Connect each component using wires that represent the electrical connections. For example, if you’re designing a simple LED circuit, you would connect the LED to a resistor and then to a power source. After you have connected all components, it is important to run an Electrical Rules Checker (ERC) provided by your software. This tool will help identify any mistakes, such as unconnected pins or incorrect component values. Fixing these issues at this stage will save you time and effort later in the design process.

4. Define the PCB Layout

Credits: pcbaaa.com

Credits: pcbaaa.com

Defining the PCB layout is a critical step in the design process. Start by determining the dimensions of your board based on the components you have chosen and the final application. Once the size is set, strategically place your components on the board. Aim to minimize trace lengths between components to enhance signal integrity and reduce potential interference. For instance, if you have a microcontroller and several sensors, position them close together to keep the connections short.

Ensure that components are oriented correctly, especially those that have specific alignment, like connectors and polarized capacitors. It’s often helpful to visualize how the PCB will be mounted in its final form—considering things like access to connectors and space for heat dissipation. This thought process can save you from layout adjustments later on.

As you define your layout, keep in mind the flow of the circuit and the logical grouping of components. For example, group power components separately from signal components to minimize noise interference. Using a grid overlay in your design software can help align components and traces for a cleaner layout, making the final PCB easier to manufacture and assemble.

- Choose the PCB shape and size

- Determine the layer stack-up

- Position all components based on the schematic

- Keep high-frequency components close to each other

- Follow best practices for trace width and spacing

- Plan for thermal and mechanical requirements

- Include mounting holes and cutouts if necessary

5. Route Traces

Routing traces involves connecting the components on your PCB using copper paths. Start by selecting the appropriate tool in your PCB design software to draw these traces. Aim for shorter traces whenever possible, as they reduce resistance and minimize interference. For instance, if you are connecting a microcontroller to a sensor, try to keep the trace length as short as you can to enhance performance.

When routing, consider the width of your traces. Wider traces are necessary for power and ground connections to handle higher currents without overheating. A common practice is to use a trace width calculator to determine the appropriate width based on the expected current.

Additionally, use vias to connect traces between different layers, especially in multi-layer PCBs. This allows you to route traces efficiently without crossing over other components or traces. However, try to limit the number of vias, as each one can add inductance and resistance to your circuit.

While routing, also be mindful of the placement of high-frequency signals. Keeping these traces away from noisy components, like power traces, helps to maintain signal integrity. Lastly, it’s essential to keep a consistent spacing between traces to prevent unintentional short circuits, adhering to your design rules.

6. Add Power and Ground Planes

Adding power and ground planes to your PCB design is a crucial step in ensuring reliable performance. Power planes are large areas of copper that provide a stable voltage supply to your components, while ground planes serve as a common reference point for all signals. This design technique helps to reduce electrical noise and interference, particularly in high-frequency or high-current applications. For example, if you’re designing a circuit for an audio amplifier, having a solid ground plane can significantly improve sound quality by minimizing hum and buzz.

When creating these planes, it’s important to ensure they are connected properly to the relevant pins on your components. This is typically done using vias, which allow connections between different layers of the PCB. Additionally, keep in mind that wider traces for power connections can handle higher currents without overheating, which enhances the overall reliability of your board. By implementing power and ground planes effectively, you can create a robust PCB that performs well under various conditions.

7. Place Silkscreen and Other Markings

Credits: pcbgogo.com

Credits: pcbgogo.com

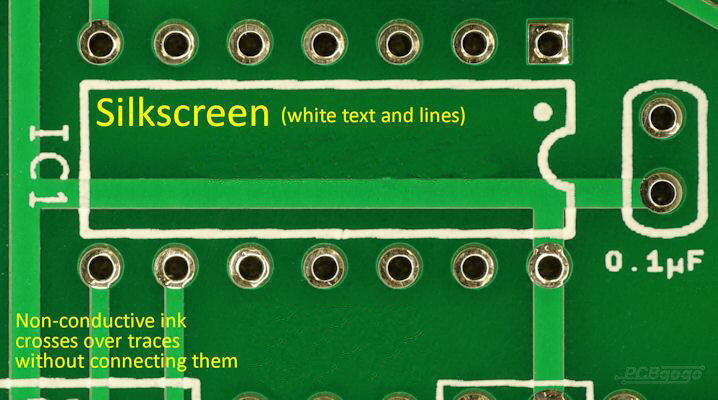

Placing silkscreen and other markings on your PCB is an important step that enhances usability and readability. The silkscreen layer is where you add text and symbols that help identify components, pin numbers, and orientation. For example, labeling parts like resistors and capacitors with their values makes assembly easier. It’s also common to include your logo or version number to mark your design.

When positioning these markings, ensure they do not overlap with the pads for components or the traces connecting them. This avoids any potential issues during manufacturing or soldering. Use a contrasting color for the silkscreen to improve visibility; typically, white or yellow text on a green board works well. Pay attention to the font size and style to keep everything legible and clear. Remember, these markings will assist anyone who works on the board in the future, so clarity is key.

8. Verify with Design Rule Check

Before finalizing your design, it’s crucial to run a Design Rule Check (DRC). This process ensures that your PCB layout adheres to specific design rules, preventing potential manufacturing issues. Most PCB design software offers a built-in DRC tool that checks for spacing violations, unconnected traces, and other critical errors. For example, a common rule is to maintain a minimum distance between traces to avoid short circuits. If your design fails the DRC, the software will highlight the problematic areas, allowing you to make necessary adjustments. By verifying your design with DRC, you can catch issues early, saving time and costs in the manufacturing process.

9. Generate Gerber Files

After verifying your design, the next crucial step is to generate Gerber files. Gerber files are the standard format used by PCB manufacturers to produce your board. These files provide detailed information about each layer of your PCB, including copper layers, solder mask, silkscreen, and any other relevant details. Most PCB design software has an export function specifically for this purpose.

When exporting, ensure that you select the correct settings for your manufacturer. Typically, you will need to generate several files, including:

– Copper Layer Files: These show the layout of the traces and pads for each layer.

– Solder Mask Layers: These indicate where solder mask should be applied, protecting certain areas from solder.

– Silkscreen Layers: These files contain information about text and graphics on the PCB surface.

It’s also important to include a drill file, which specifies the locations and sizes of holes required for component leads and vias. Once you have generated all the necessary Gerber files, review them using a Gerber viewer. This helps you confirm that everything looks correct before sending them off to a manufacturer. A small mistake in this step can lead to costly errors in your PCB production.

10. Order Your PCB

After generating your Gerber files, the next step is to order your PCB from a manufacturer. There are many online PCB fabrication services, such as JLCPCB, PCBWay, and OshPark, that make this process straightforward. You’ll need to upload your Gerber files to their platform, where you can specify the details of your PCB, including the size, number of layers, and the type of material you want to use.

When placing your order, consider the following aspects:

– Quantity: Many manufacturers offer discounts for larger orders, so it’s worth ordering a few extra boards in case of errors during assembly or future projects.

– Material: Common materials include FR-4, which is suitable for most applications, but you might also consider options like aluminum for specific thermal requirements.

– Thickness: Standard PCB thickness is typically 1.6 mm, but you can choose thinner or thicker boards based on your project needs.

– Lead Time: Check how long it will take for the boards to be manufactured and shipped. Some services offer expedited options for a higher fee.

Once you finalize your order, you will receive a confirmation, and the manufacturer will begin production. In a few days to weeks, depending on the service, you will have your custom PCBs ready for assembly. This step is exciting, as it marks the transition from design to physical product.

Frequently Asked Questions

1. What is a PCB and why is it important in electronics?

A PCB, or Printed Circuit Board, is a board used to connect electronic components. It’s important because it helps organize and support these components, allowing devices to work properly.

2. Do I need special software to design a PCB?

Yes, you usually need PCB design software. These programs help you create your board layout and also ensure that your design works correctly.

3. What materials are used to make a PCB?

PCBs are primarily made of materials like fiberglass or epoxy resin, along with copper for the electrical connections.

4. Can I design a PCB without any prior experience?

Absolutely! With beginner guides and tutorials available, even those with no prior experience can learn to design PCBs step by step.

5. What are the common mistakes to avoid when designing a PCB?

Common mistakes include not double-checking connections, ignoring component placement, and failing to consider the size and heat dissipation requirements of the circuit.

TL;DR This beginner’s guide outlines ten essential steps for designing your own printed circuit board (PCB), including understanding circuit requirements, choosing design software, creating schematics, defining layouts, routing traces, adding power planes, placing markings, verifying designs, generating Gerber files, and ordering your PCB. With practice, you can produce functional and quality designs.